Acetic anhydride is produced by carbonylation of methyl acetate in a process that is similar to the Monsanto Acetic Acid process. The process monitoring methods in this book are tested on the data collected from the process simulation for the Tennessee Eastman process TEP.

Generalized Transformer In Fault Diagnosis Of Tennessee Eastman Process Springerlink

All datasets have training 500 samples and testing 960.

. Catalytic cycle of Acetic anhydride processMonsanto Acetic Acid process - httpsyoutubeJ9Pxy6vPOWcchemistry chemtuber catalysisPlaylists Links Crash. Scholarship for Tobias Jockenhövel from the Ernst von Siemens-Foundation. The most widely used benchmark consists of 22 datasets 21 of which Fault 121 contain faults and 1 Fault 0 is fault-free.

INTRODUCTION Although being a rather old process model the Tennessee Eastman Process model of Downs and Vogel 1993 re- mains an important tool throughout all disciplines of the system theory for the purpose of comparative studies or validation of algorithms eg. This Notebook has been released under the Apache 20 open source license. 3 forks Releases No releases published.

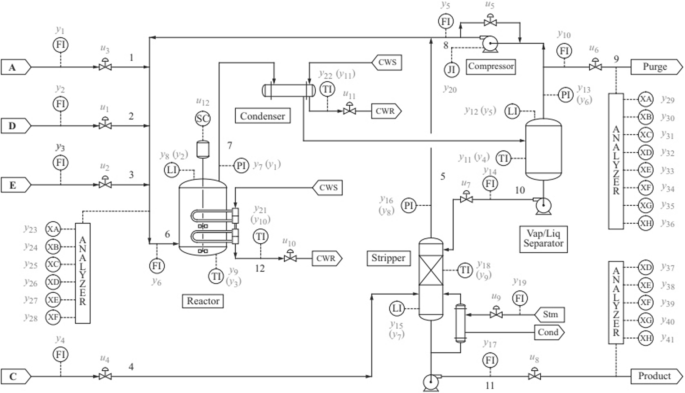

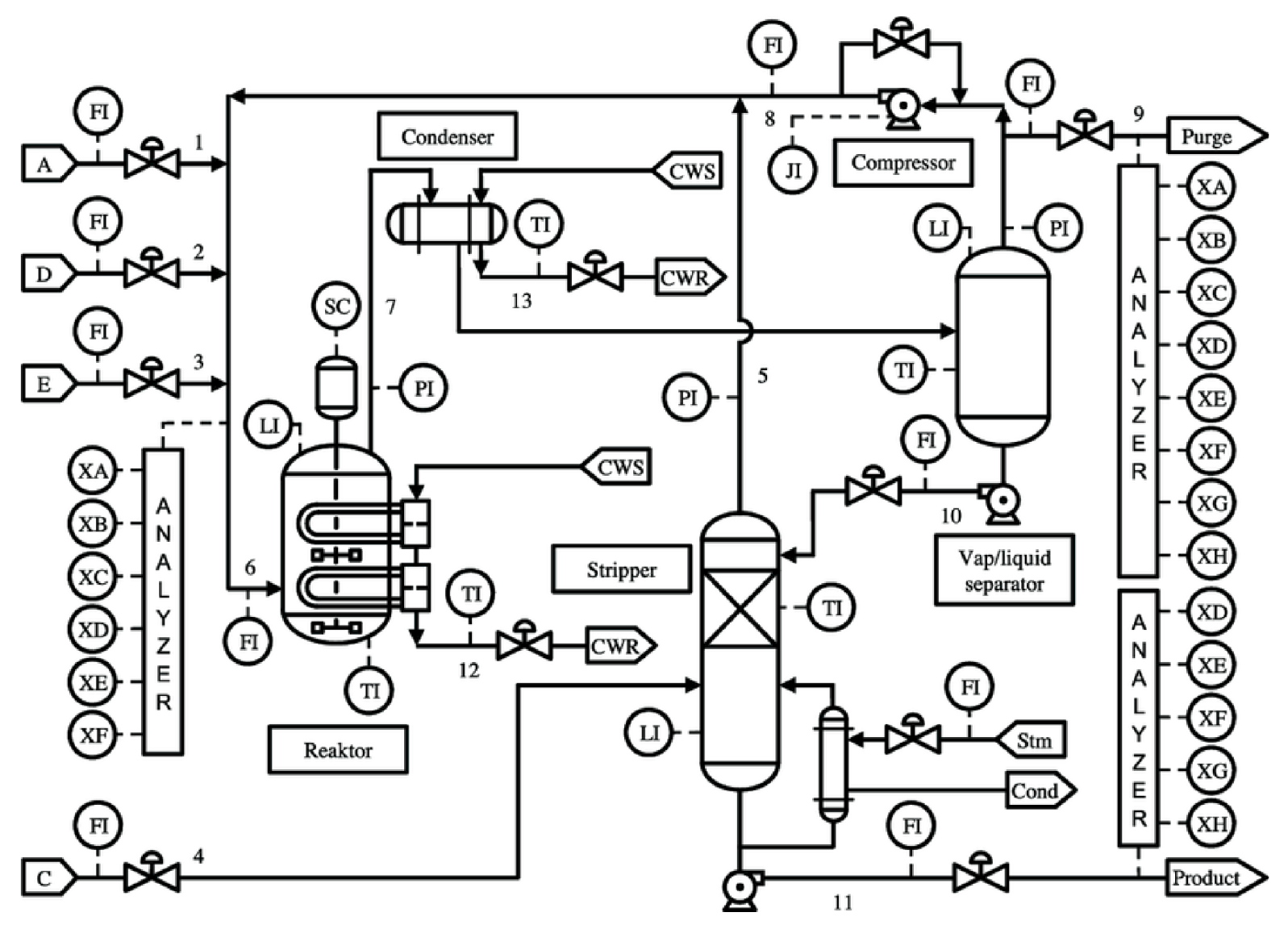

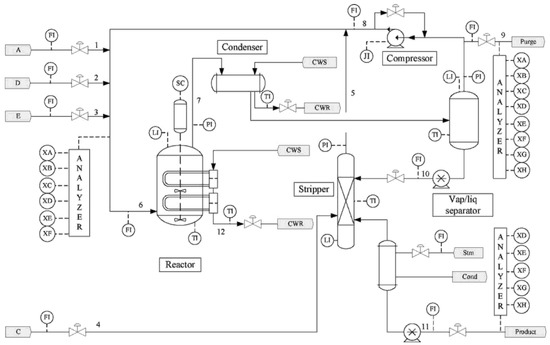

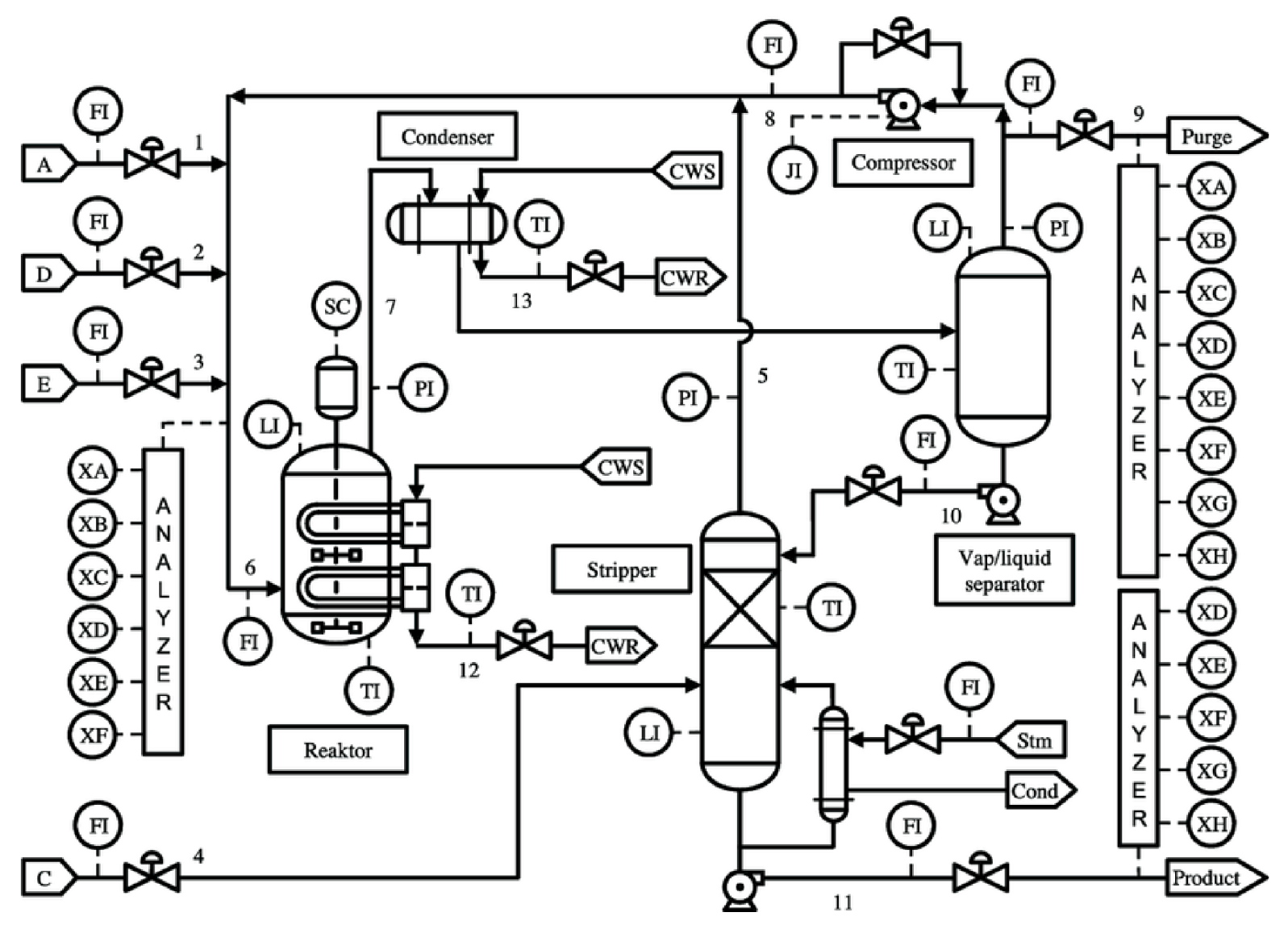

The process has eight components including four reactants A C D and E two products an inert and a byproduct. It is available in repository. This is a FORTRAN model of the Tennessee Eastman process control challenge problem.

The TE problem was introduced by Downs and Vogel in 1990. This is a nonlinear open-loop unstable process that has been used in many studies as a case study for plant-wide control statistical process monitoring. Catalytic cycle is explaine.

Tennessee-eastman-process-simulation-data Python Tennessee Eastman Process Simulation Dataset. Instead many academics in process monitoring perform studies based on data collected from computer simulations of a chemical process. A two-phase reactor where an exothermic reaction occurs a separator a stripper a compressor and a mixer.

Fulltext Access 12 Pages 2017. The original paper presented a model of the industrial chemical process named Tennessee Eastman Process and a model-based TEP simulator for data generation. Fulltext Access 31 Pages 2018.

The TEP has been widely used by the process monitoring community as a source of. Multi-model quality prediction approach using fuzzy C-means clustering and support vector regression. N1 - Funding Information.

Fault diagnosis in Yin et al. Tennessee Eastman Process Control Challenge Problem. This research project was funded by a personal PhD.

Selection of non-zero loadings in sparse principal component analysis. No packages published. 2012 system identification in Bathelt and Je- lali.

Gases interact exothermically inside the reactor. Automatically generated derivative code. The output consists of two products.

Fault Detection and Diagnosis in dynamic systems using Weightless Neural Networks. The liquid enters the stripping column where the fractions are separated. The products leave the reactor as vapors and are fed into the condenser then into the vapor-liquid separator.

AU - Biegler Lorenz T. Download scientific diagram Tennessee Eastman process. The following zip archives contain Matlab and Fortran code described in the papers Nonlinear Model Predictive Control of the Tennessee Eastman Challenge Process Computers Chemical Engineering Vol.

Production ready statistical process monitoring and anomaly detection program for a typical chemical production plant Resources. The basic idea of DAOI-ELM is to incorporate the Gram-Schmidt orthogonalization method and driving amount into an incremental extreme learning machine I-ELM. AU - Wächter Andreas.

T1 - Dynamic optimization of the Tennessee Eastman process using the OptControlCentre. This paper proposes an orthogonal incremental extreme learning machine based on driving amount DAOI-ELM for recognizing the faults of the Tennessee-Eastman process TEP. The sparsity pattern shown on the right has been automatically generated using DAEPACK.

The model consists of 50 equation and 50 variables. Up to 20 cash back The Tennessee Eastman Process TEP model consists of four main units. Up to 10 cash back The Tennessee Eastman TE process is a chemical testing experimental platform that developed from a realistic chemical joint reaction process.

A combined monitoring scheme with fuzzy logic filter for plant-wide Tennessee Eastman Process fault detection. AU - Jockenhövel Tobias. A two-phase reactor where an exothermic reaction occurs a separator a stripper a compressor and a mixer.

History Version 1 of 1. 961-9811995 and Nonlinear Modeling and State Estimation for the Tennessee Eastman Challenge Process ibid pp. The Tennessee Eastman process is a typical industrial process that consists of five main process units.

The Tennessee Eastman process is a typical industrial process that consists of five main process units.

Flow Sheet Of The Tennessee Eastman Process Tep Indicating The Download Scientific Diagram

Flow Chart Of The Tennessee Eastman Process Download Scientific Diagram

Tennessee Eastman Chemical Process 27 30 Download Scientific Diagram

Flow Sheet Of The Tennessee Eastman Process Tep Indicating The Download Scientific Diagram

Revision Of The Tennessee Eastman Process Model Available Remech

Tennessee Eastman Fault Detection With Pca And Lgb Kaggle

Processes Free Full Text A Novel Mutual Information And Partial Least Squares Approach For Quality Related And Quality Unrelated Fault Detection Html

Tennessee Eastman Te Process Diagram Source 17 Download Scientific Diagram

Pdf Study On Support Vector Machine Based Fault Detection In Tennessee Eastman Process Semantic Scholar

Tennessee Eastman Te Process Diagram Source 17 Download Scientific Diagram

Schematic Of The Tennessee Eastman Process Yin Et Al 2012 Download Scientific Diagram

Schematic Of The Tennessee Eastman Process Yin Et Al 2012 Download Scientific Diagram

Flow Chart Of The Tennessee Eastman Process Download Scientific Diagram

Schematic Of The Tennessee Eastman Process Yin Et Al 2012 Download Scientific Diagram

Process Fault For Tennessee Eastman Process Download Table

Flow Chart Of The Tennessee Eastman Process Download Scientific Diagram

Tennessee Eastman Te Process Diagram Source 17 Download Scientific Diagram

Sensors Free Full Text Fault Detection And Diagnosis Using Combined Autoencoder And Long Short Term Memory Network Html